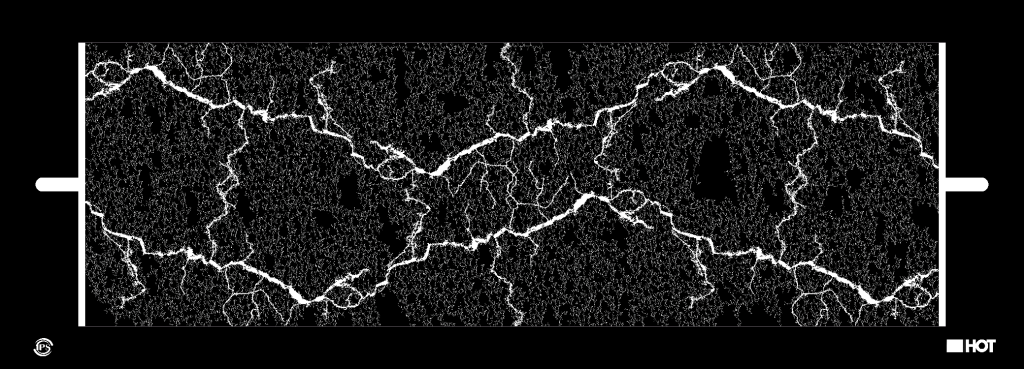

See what’s happening inside your rock

Microfluidic fluid analysis technology is an integral part of our laboratory workflows at fluidXlab. We integrate microfluidics to complement or replace conventional measurement methods for IOR/EOR, H2 storage and CCS/CCUS applications. More than that, our understanding of the full range of experiments allows us to combine the best of both worlds and to create valuable synergies.

In short: We are able to provide you with an accurate window to your reservoir, enabling you to see what’s happening inside your rock.

WHY CHOOSE fluidXlab?

The fast and economical visualisation of fluid dynamic flow and processes helps reduce costs and accelerates investigations. This makes microfluidics an ideal solution for energy companies, IOR/EOR & PVT departments, people working in energy storage and fluid analytics (researchers, engineers), as well as researchers in the field of low carbon/environmental gases applications.

Good to know: Accurate and efficient fluid analysis performed at extreme conditions and under tight deadlines can also accelerate the implementation of net-zero projects. This ultimately results in faster decarbonisation. Additionally, employing microfluidic testing methods minimises the laboratory's environmental impact, as fewer chemicals are used in the experiments.

Benefits of our microfluidics fluid analysis technology

Microfluidics technology by fluidXlab is suitable for a range of applications and offers many advantages over traditional methods, including – but not limited to – the ability to process small volumes of fluid more quickly and with greater accuracy.

Small fluid volume & cost efficiency

Small fluid volume & cost efficiency

Fast results & screening

Fast results & screening

Visualisation

Visualisation

Small in size – big in visualisation!

Scope of microfluidics services

Phase behaviour & PVT

- Phase diagram (dew point, bubble point)

- Fluid properties (density, viscosity)

- Fluid interactions (MMP, diffusion)

- EOR effect (swelling, micro/macro-emulsions)

- High Pressure, High Temperature (HPHT)

- H2 & CO2 compatible

Flow assurance & conformance control

- Asphaltene

- Wax

- Salts precipitations

- High Pressure, High Temperature (HPHT)

- H2 & CO2 compatible

Improved oil recovery / enhanced oil recovery (IOR / EOR)

- Flow through porous media (saturation profiles, recovery factor)

- Chemical IOR (polymer, alkaline, surfactant)

- Foam injection

- Gas injection

- Thermal EOR

- Microbial

- High Pressure, High Temperature (HPHT)

- H2 & CO2 compatible

Customised lab-on-a-chip (LOC)

- High-pressure fluid testing micromodels (MMP, flow assurance, dew point)

- Porous media chips based on µCT and thin sections

- High Pressure / High Temperature (HPHT)

- H2 & CO2 compatible

Discover what others say about fluidXlab

We invited HOT fluidXlab to provide laboratory support in our research of potential candidates for underground hydrogen storage (UHS) in Austria. HOT fluidXlab never ceased to impress with their professionalism, persistence and surpassing any our expectations in delivering highly valuable and reliable data.

Dr. Clemens T., Senior Reservoir Engineering Advisor at OMV Energy

Publications

Our most recent work was featured in the following publications:

Selecting EOR Polymers through Combined Approaches—A Case for Flooding in a Heterogenous Reservoir

Borovina, Ante, Rafael E. Hincapie, Torsten Clemens, Eugen Hoffmann, and Jonas Wegner. 2022.

Polymers. 2022; 14(24):5514.

https://doi.org/10.3390/polym14245514

Real structure micromodels based on reservoir rocks for enhanced oil recovery (EOR) applications

Calvin Lumban Gaol, Jonas Wegner and Leonhard Ganzer

Lab on a Chip, 2020, 20. Jg., Nr. 12, S. 2197-2208.

https://doi.org/10.1039/D0LC00257G

Coupling Microfluidics Data with Core Flooding Experiments to Understand Sulfonated/Polymer Water Injection

Tahir, Muhammad, Rafael E. Hincapie, Nils Langanke, Leonhard Ganzer, and Philip Jaeger. 2020.

Polymers 12, no. 6: 1227.

https://doi.org/10.3390/polym12061227

Labwork Matters

BROCHURE

DOWNLOAD

Unlock the power of microfluidics!

fluidXlab offers cutting-edge microfluidic fluid analysis technology that gives you the power to see inside your rock. It lets you build a window to your reservoir, enabling you to make informed decisions fast and with the best possible knowledge. To learn more about our solutions and how they can help you streamline your operations, get in touch with us today!