ACCELERATING YOUR PATH TO NET ZERO

The unique thermodynamic properties of CO2 and phase behaviour compared to natural gas present new challenges during operational events such as start-up, shutdown, depressurisation, fluctuating CO2 supply, and potential leaks. Moreover, impurities will be present in CO2 at various stages, from capture to storage. fluidXlab revolutionises the characterisation of CO2 with new technology that requires less fluid volumes than traditional methods, reducing time-to-field deployment and project risk.

Carbon Management

Leveraging years of expertise, fluidXlab specialises in comprehensive CO2 management solutions across 3 key areas:

CO2 Capture and Transport

CO2 Capture and Transport

Co2 Geological Storage

Solutions for Integrity and Performance Assessment

Services Ensuring Safe CO2 Geological Storage

This is where fluidXlab steps in. We offer a comprehensive suite of testing services, including caprock integrity, SCAL (Special Core Analysis Laboratories), rock and fluid interaction assessments, phase behaviour studies, and flow assurance analyses, fluid characterisation and petrophysical properties measurements. Our solutions minimise project risks and maximise the success of your CCS project.

- Solid Precipitation

- Hydrate Formation

- Chemical Screening

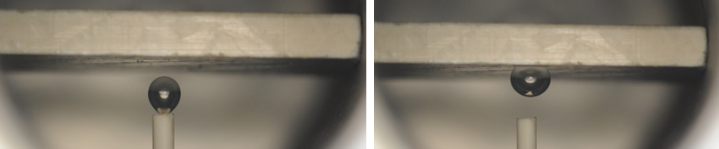

- Contact Angle

- Gas Adsorption Test

- Specific Surface Area (BET)

- Batch Reactor

- Dynamic Viscosity

- Density

- Decomposition Test

- Recombination/Synthesis

- Relative Permeability

- Capillary Pressure

- Core Analysis

- Injectivity Test

- Core Flooding

- Reservoir Rock Mineralogy, Porosity, Permeability

- Cap Rock Mineralogy

- Constant Composition Expansion (CCE)

- Constant Volume Depletion (CVD)

- Vapor-Liquid Equilibrium (VLE)

- Diffusion (Gas-Gas, Gas-Liquid)

- Solubility (CO2 in Brine, Water in CO2)

- Interfacial Tension (IFT)

- Dispersion Test

- Threshold Pressure

Co2 Enhanced Hydrocarbon Recovery

Unlocking Trapped Hydrocarbons while Injecting CO2

fluidXlab is at the forefront of pioneering research, conducting a diverse range of laboratory tests like phase behaviour, flow assurance, rock-fluid characterisation, petrophysical properties, fluid properties and SCAL aimed at utilising captured CO2 for enhanced hydrocarbon recovery. Our cutting-edge experiments involve fluid and gas mixtures, including CO2, and hydrocarbons, all while adhering to the highest health, safety, and environmental standards. These critical services contribute to maximising the benefits of the recovery process while minimising any potential risks.

De-Risk CO2-Enhanced Hydrocarbon Recovery Projects

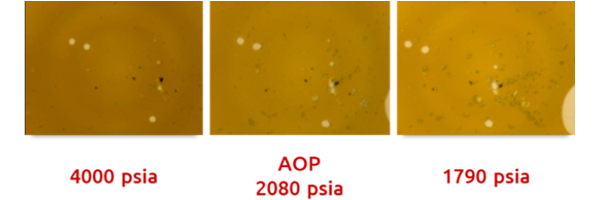

- Asphaltene Onset Pressure / Temperature

- Wax Appearance Temperature

- Salt Precipitation

- Chemical Screening

- Contact Angle

- Gas Adsorption

- Specific Surface Area (BET)

- Batch Reactor

- Composition

- Density

- Dynamic Viscosity

- Recombination/Synthesis

- Relative Permeability

- Capillary Pressure

- Core Analysis

- Injectivity Test

- Core Flooding

- Reservoir Rock Mineralogy

- Cap Rock Mineralogy

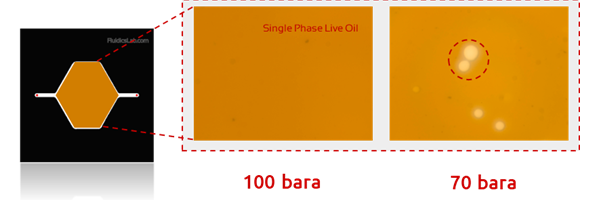

- Constant Composition Expansion (CCE)

- Constant Volume Depletion (CVD)

- Differential Liberation Expansion (DLE)

- Swelling and Separator

- Minimum Miscibility Pressure (MMP) – Slim Tube*/ Rising Tube

- Multiple Contact

- Diffusion (Gas-Gas, Gas-Liquid)

- Solubility (CO2 in Brine, Water in CO2)

- Interfacial Tension (IFT)

- Dispersion Test

(CCE Test)

Co2 Capture & Transport

Enable Efficient and Safe Operations

Supporting Your CO2 Transport and Capture Technologies

- Magnetic Suspension Balance (MSB)

- PVT Cell

- Wetted Wall Column and Continuous Flow System

- Solid Precipitation

- Hydrates Formation Analysis

- Dynamic Viscosity

- Density

- Composition

- Recombination/Synthesis

- Vapour-Liquid (VL) and Vapour-Liquid-Liquid (VLL) Phase Behaviour with Impurities

- Solubility (CO2 in Liquid / Liquid in CO2)

- Pipe Material Studies

Partnering with fluidXlab enables you to confidently address the complexities of CO2 transportation, paving the way for a cleaner and more sustainable future.

Advanced Carbon Management Solutions